Maximizing Efficiency: A Guide to Selecting the Best API Tubing for Your Oilfield Operations

Published on:

2024-05-11

# Introduction In the oil and gas industry, the selection of the right API tubing is crucial for the success of your operations. With various options available in the market, it can be overwhelming to choose the best tubing that meets your specific needs. This comprehensive guide will walk you through the essential factors to consider when selecting API tubing for your oilfield operations. ## What

# Introduction

In the oil and gas industry, the selection of the right API tubing is crucial for the success of your operations. With various options available in the market, it can be overwhelming to choose the best tubing that meets your specific needs. This comprehensive guide will walk you through the essential factors to consider when selecting API tubing for your oilfield operations.

## What is API Tubing?

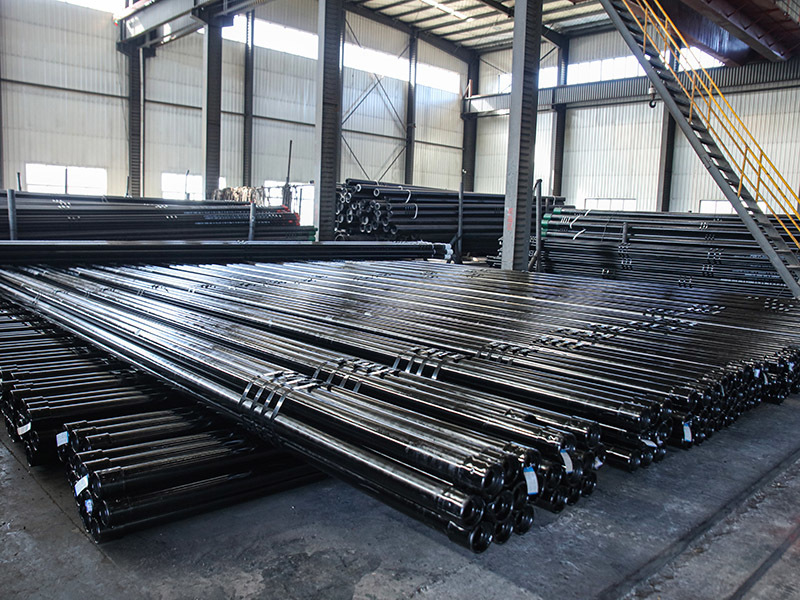

API tubing refers to the pipes used in oil and gas wells to transport produced fluids to the surface. These tubes are designed to withstand high-pressure environments and harsh operating conditions commonly found in oilfields.

## Why Choosing the Right API Tubing is Important

Selecting the appropriate API tubing is vital for ensuring the efficiency, safety, and longevity of your oilfield operations. The right tubing can help maximize production output, minimize downtime, and reduce overall operational costs.

# Factors to Consider When Choosing API Tubing

When selecting API tubing for your oilfield operations, several key factors should be taken into account to ensure optimal performance and reliability.

## 1. Material Quality

The material quality of the API tubing is crucial for its performance and longevity. High-quality materials, such as carbon steel or alloy steel, can withstand corrosion, high temperatures, and high-pressure environments commonly found in oilfields.

## 2. Size and Dimensions

The size and dimensions of the API tubing should be chosen based on the specific requirements of your oilfield operations. Consider factors such as flow rate, pressure rating, and depth of the well when selecting the appropriate tubing size.

## 3. API Specification

Ensure that the API tubing meets the required specifications set by the American Petroleum Institute (API). API specifications define the technical requirements for tubing materials, dimensions, and performance standards to ensure compatibility and reliability in oilfield operations.

## 4. Corrosion Resistance

Corrosion is a common issue in oilfield operations due to exposure to harsh chemicals and environmental conditions. Choose API tubing with high corrosion resistance properties to prevent degradation and prolong the lifespan of the tubing.

## 5. Cost-Effectiveness

Consider the overall cost-effectiveness of the API tubing, including initial purchase costs, maintenance requirements, and longevity. It is essential to strike a balance between quality and cost to ensure optimal performance and value for your oilfield operations.

# Frequently Asked Questions

## Q: What is the difference between API tubing and casing?

A: API tubing is used to transport fluids from the reservoir to the surface, while casing is used to line the wellbore and provide structural support.

## Q: How do I determine the right API tubing size for my well?

A: The API tubing size should be selected based on factors such as flow rate, pressure rating, and depth of the well.

## Q: What are the common materials used in API tubing?

A: Carbon steel and alloy steel are commonly used materials for API tubing due to their high strength and corrosion resistance properties.

## Q: How can I ensure the API tubing meets the required specifications?

A: It is essential to verify that the API tubing meets the API specifications for materials, dimensions, and performance standards.

## Q: What are the key benefits of choosing the right API tubing for oilfield operations?

A: Selecting the right API tubing can help maximize production output, minimize downtime, and reduce operational costs in oilfield operations.

# Conclusion

Choosing the right API tubing for your oilfield operations is a critical decision that can impact the efficiency and success of your operations. By considering factors such as material quality, size, API specifications, corrosion resistance, and cost-effectiveness, you can ensure optimal performance and reliability in your oilfield operations. Make informed decisions when selecting API tubing to maximize efficiency and productivity in your oilfield operations.

In the oil and gas industry, the selection of the right API tubing is crucial for the success of your operations. With various options available in the market, it can be overwhelming to choose the best tubing that meets your specific needs. This comprehensive guide will walk you through the essential factors to consider when selecting API tubing for your oilfield operations.

## What is API Tubing?

API tubing refers to the pipes used in oil and gas wells to transport produced fluids to the surface. These tubes are designed to withstand high-pressure environments and harsh operating conditions commonly found in oilfields.

## Why Choosing the Right API Tubing is Important

Selecting the appropriate API tubing is vital for ensuring the efficiency, safety, and longevity of your oilfield operations. The right tubing can help maximize production output, minimize downtime, and reduce overall operational costs.

# Factors to Consider When Choosing API Tubing

When selecting API tubing for your oilfield operations, several key factors should be taken into account to ensure optimal performance and reliability.

## 1. Material Quality

The material quality of the API tubing is crucial for its performance and longevity. High-quality materials, such as carbon steel or alloy steel, can withstand corrosion, high temperatures, and high-pressure environments commonly found in oilfields.

## 2. Size and Dimensions

The size and dimensions of the API tubing should be chosen based on the specific requirements of your oilfield operations. Consider factors such as flow rate, pressure rating, and depth of the well when selecting the appropriate tubing size.

## 3. API Specification

Ensure that the API tubing meets the required specifications set by the American Petroleum Institute (API). API specifications define the technical requirements for tubing materials, dimensions, and performance standards to ensure compatibility and reliability in oilfield operations.

## 4. Corrosion Resistance

Corrosion is a common issue in oilfield operations due to exposure to harsh chemicals and environmental conditions. Choose API tubing with high corrosion resistance properties to prevent degradation and prolong the lifespan of the tubing.

## 5. Cost-Effectiveness

Consider the overall cost-effectiveness of the API tubing, including initial purchase costs, maintenance requirements, and longevity. It is essential to strike a balance between quality and cost to ensure optimal performance and value for your oilfield operations.

# Frequently Asked Questions

## Q: What is the difference between API tubing and casing?

A: API tubing is used to transport fluids from the reservoir to the surface, while casing is used to line the wellbore and provide structural support.

## Q: How do I determine the right API tubing size for my well?

A: The API tubing size should be selected based on factors such as flow rate, pressure rating, and depth of the well.

## Q: What are the common materials used in API tubing?

A: Carbon steel and alloy steel are commonly used materials for API tubing due to their high strength and corrosion resistance properties.

## Q: How can I ensure the API tubing meets the required specifications?

A: It is essential to verify that the API tubing meets the API specifications for materials, dimensions, and performance standards.

## Q: What are the key benefits of choosing the right API tubing for oilfield operations?

A: Selecting the right API tubing can help maximize production output, minimize downtime, and reduce operational costs in oilfield operations.

# Conclusion

Choosing the right API tubing for your oilfield operations is a critical decision that can impact the efficiency and success of your operations. By considering factors such as material quality, size, API specifications, corrosion resistance, and cost-effectiveness, you can ensure optimal performance and reliability in your oilfield operations. Make informed decisions when selecting API tubing to maximize efficiency and productivity in your oilfield operations.