Contact

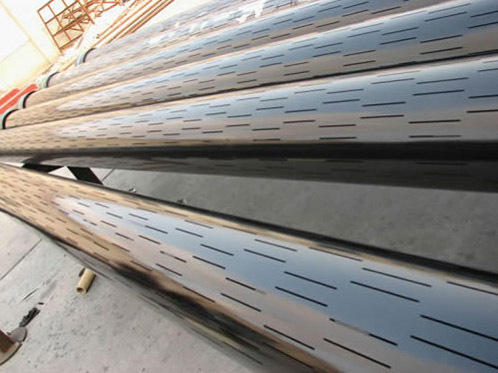

Perforated casing is manufacturing with API casing joints with size up to diameter 20". Every joints perforated is deburred internal and external. Upon request,we can drill standard or customized hole size in any number and any patten.

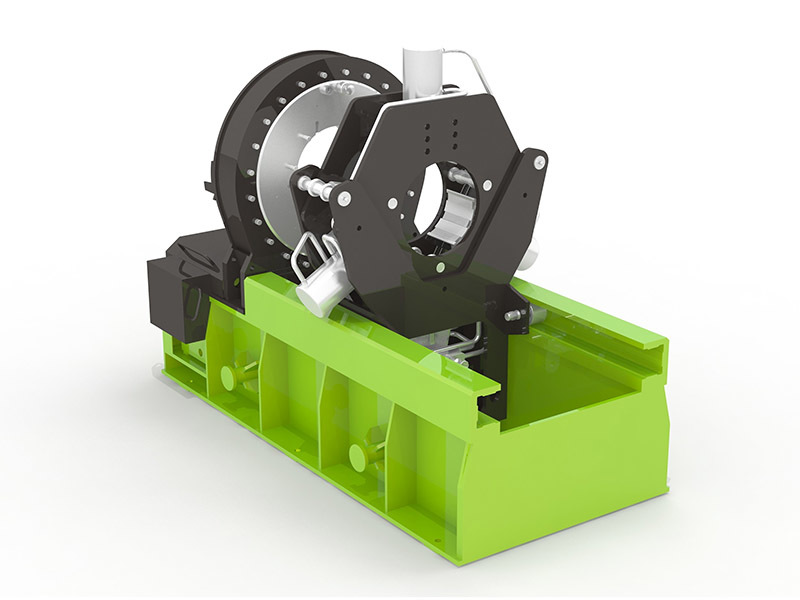

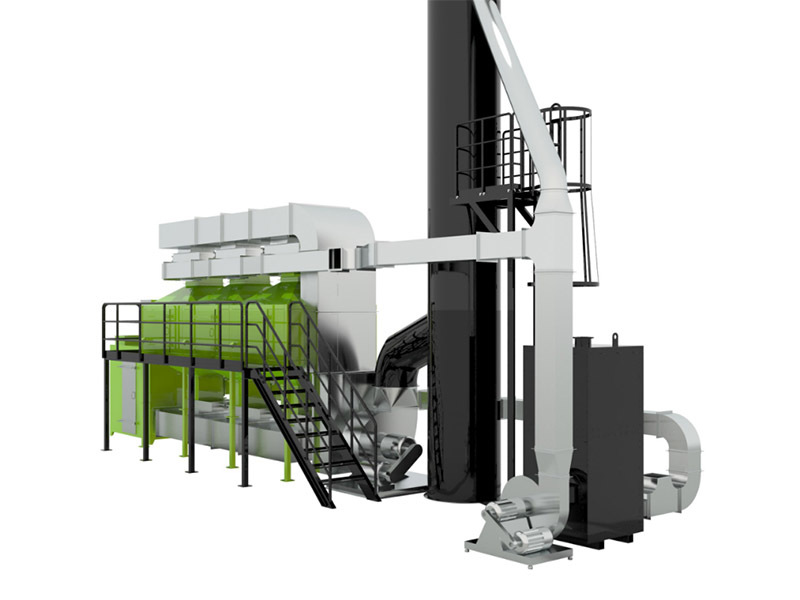

Coupling Make-up Machine For Casing & Tubing

Coupling make-up machines, mainly used in casing & tubing production factory and threads repairy shop.

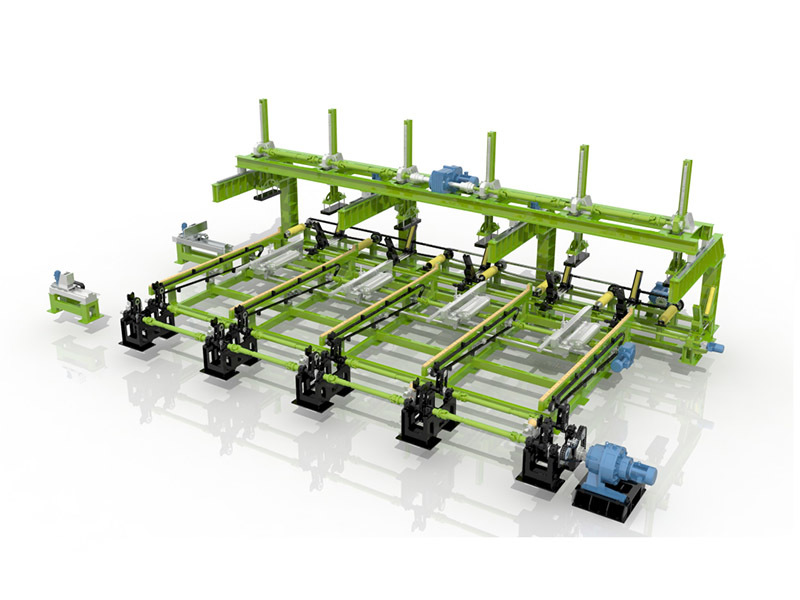

The main feature of the oil casing & tubing full-length diameter machine is controlled by PLC procedure, has simple structure ,occupa a small area, more advantages of large pipe diameter, and higher safety factor.

The equipment greatly improves the working rhythm, reduces the impact, reduces the noise, can fully adapt to the application of oil pipelines.

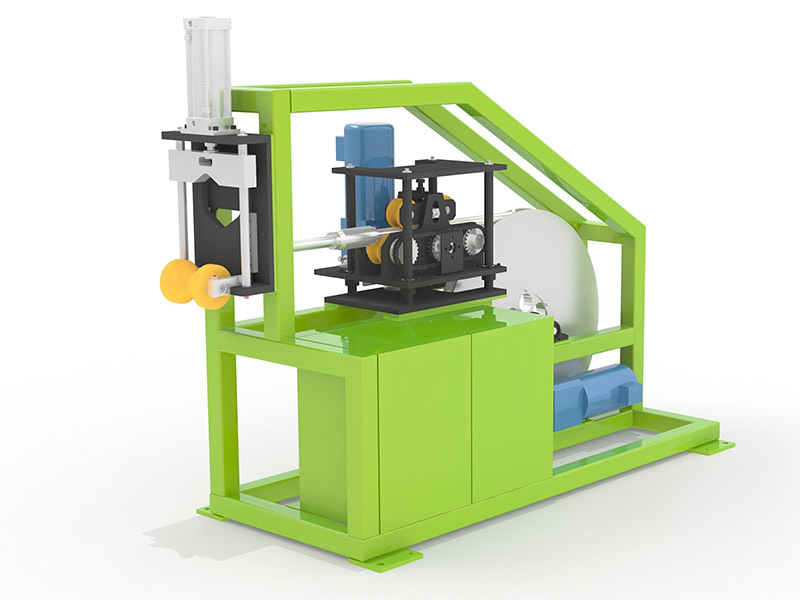

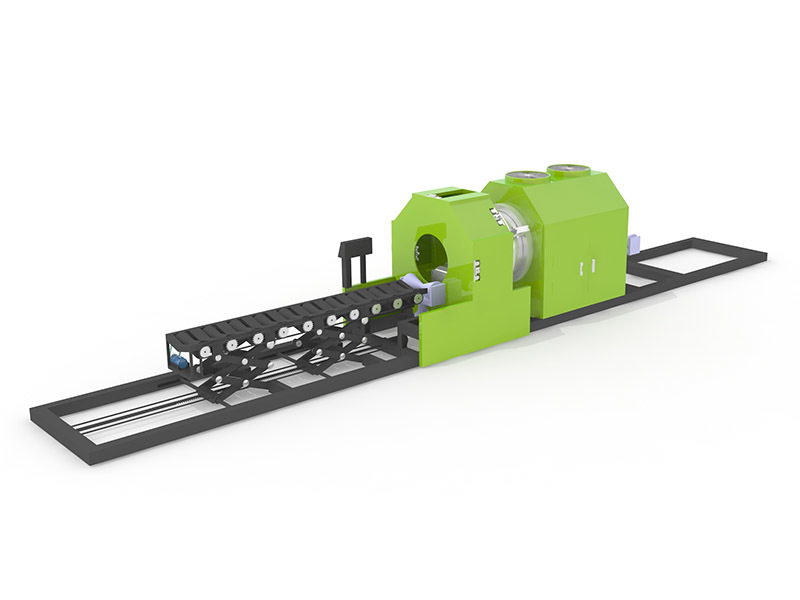

Pipe end reducing machine for casing & tubing

Pipe end reducing machine, is a machine used for reduce the pipe end diamaters so as to cut premium threads. the clamping head can apply pressure to the pipe end to compress the pipe port, enables the shrinkage of the pipe end, and during the whole process of the pipe is fixed,no restriction on the shape of the pipe.

Premium Casing & Tubing RTN-60X

RTN-60X adopts an advanced thread geometry design to reduce thread galling: pitch change on coupling thread while pin thread maintain unchanged. This design concept avoids the high initial thread loads experieneed by conventional constant pitch threads.

Premium Casing & Tubing RTH-8T

The unique combination of a metal-to-metal seal and a special relief groove in coupling provides pressure integrity for both internal and external pressure in moderate to heavy wall tubular applications.

Premium Casing & Tubing RTN-14AM

Coupling connection type, the connection strength reaches to or over that of pipe body.

Premium Casing & Tubing RTV-200P

Coupling design: Coupling critical cross sections are greater than those of the pipe body.