Understanding BC Casing: Essential Insights for Oil and Gas Operations

Published on:

2024-10-01

BC Casing, or Bore Casing, is a crucial component in the oil and gas sector, specifically in well construction and maintenance. Its primary purpose is to strengthen the borehole, provide structural integrity to the well, and prevent the collapse of surrounding geological formations. Understanding the intricacies of BC Casing is essential for professionals in the metallurgy, mining, and energy indu

BC Casing, or Bore Casing, is a crucial component in the oil and gas sector, specifically in well construction and maintenance. Its primary purpose is to strengthen the borehole, provide structural integrity to the well, and prevent the collapse of surrounding geological formations. Understanding the intricacies of BC Casing is essential for professionals in the metallurgy, mining, and energy industries, particularly those involved in drilling operations.

One of the key functions of BC Casing is to create a barrier between the wellbore and surrounding formations. This barrier aids in preventing the migration of fluids, such as oil, gas, and groundwater, thereby maintaining the environmental integrity of the site. Additionally, BC Casing serves to protect the well from external pressures and stresses, which can significantly affect drilling operations. By preventing the influx of potentially hazardous materials, BC Casing plays a vital role in operational safety.

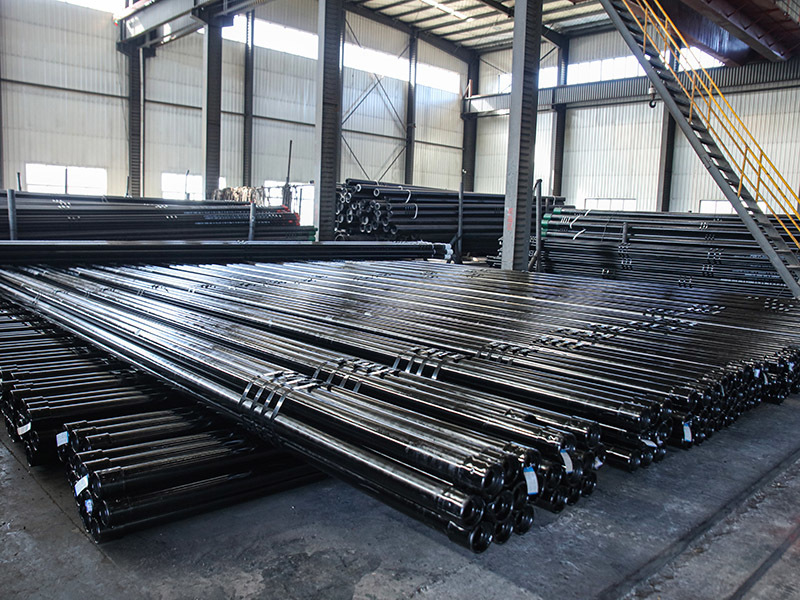

BC Casing is available in various materials, with steel being one of the most commonly used due to its high strength and durability. The choice of material largely depends on the specific conditions of the drilling site, including temperature, pressure, and the type of formations being encountered. The casing must withstand not only the weight of the surrounding earth but also the pressures exerted by the fluids within the wellbore.

Installation of BC Casing involves a series of precise steps. After drilling the borehole to the required depth, the casing is inserted and then cemented into place. This cementing process is critical as it ensures that the casing is securely anchored, preventing any movement that could compromise the well’s structural integrity. Proper installation and maintenance of BC Casing are essential to mitigate risks associated with well blowouts or leaks.

Furthermore, BC Casing plays a significant role in the overall efficiency of drilling operations. By stabilizing the wellbore, it allows for the continuous extraction of hydrocarbons while minimizing the risk of costly downtime due to structural failures. As energy demands continue to rise, the importance of reliable and efficient well construction becomes increasingly paramount.

In conclusion, BC Casing is an integral element of modern oil and gas operations. By ensuring the structural integrity of wells and preventing environmental contamination, it contributes significantly to the success and safety of drilling projects. Professionals in the metallurgy and energy sectors need to be well-versed in the properties and applications of BC Casing to optimize their operations and uphold industry standards. Understanding its function and importance not only enhances operational efficiency but also promotes a safer working environment in a demanding industry.

One of the key functions of BC Casing is to create a barrier between the wellbore and surrounding formations. This barrier aids in preventing the migration of fluids, such as oil, gas, and groundwater, thereby maintaining the environmental integrity of the site. Additionally, BC Casing serves to protect the well from external pressures and stresses, which can significantly affect drilling operations. By preventing the influx of potentially hazardous materials, BC Casing plays a vital role in operational safety.

BC Casing is available in various materials, with steel being one of the most commonly used due to its high strength and durability. The choice of material largely depends on the specific conditions of the drilling site, including temperature, pressure, and the type of formations being encountered. The casing must withstand not only the weight of the surrounding earth but also the pressures exerted by the fluids within the wellbore.

Installation of BC Casing involves a series of precise steps. After drilling the borehole to the required depth, the casing is inserted and then cemented into place. This cementing process is critical as it ensures that the casing is securely anchored, preventing any movement that could compromise the well’s structural integrity. Proper installation and maintenance of BC Casing are essential to mitigate risks associated with well blowouts or leaks.

Furthermore, BC Casing plays a significant role in the overall efficiency of drilling operations. By stabilizing the wellbore, it allows for the continuous extraction of hydrocarbons while minimizing the risk of costly downtime due to structural failures. As energy demands continue to rise, the importance of reliable and efficient well construction becomes increasingly paramount.

In conclusion, BC Casing is an integral element of modern oil and gas operations. By ensuring the structural integrity of wells and preventing environmental contamination, it contributes significantly to the success and safety of drilling projects. Professionals in the metallurgy and energy sectors need to be well-versed in the properties and applications of BC Casing to optimize their operations and uphold industry standards. Understanding its function and importance not only enhances operational efficiency but also promotes a safer working environment in a demanding industry.